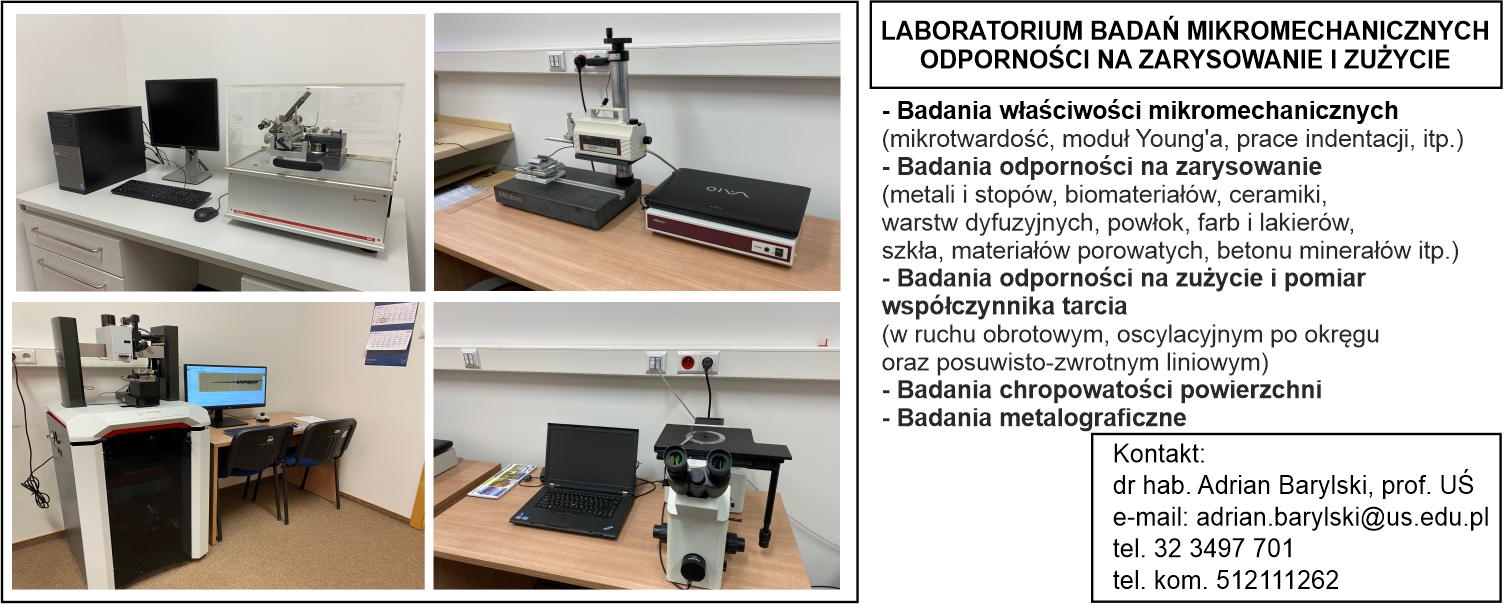

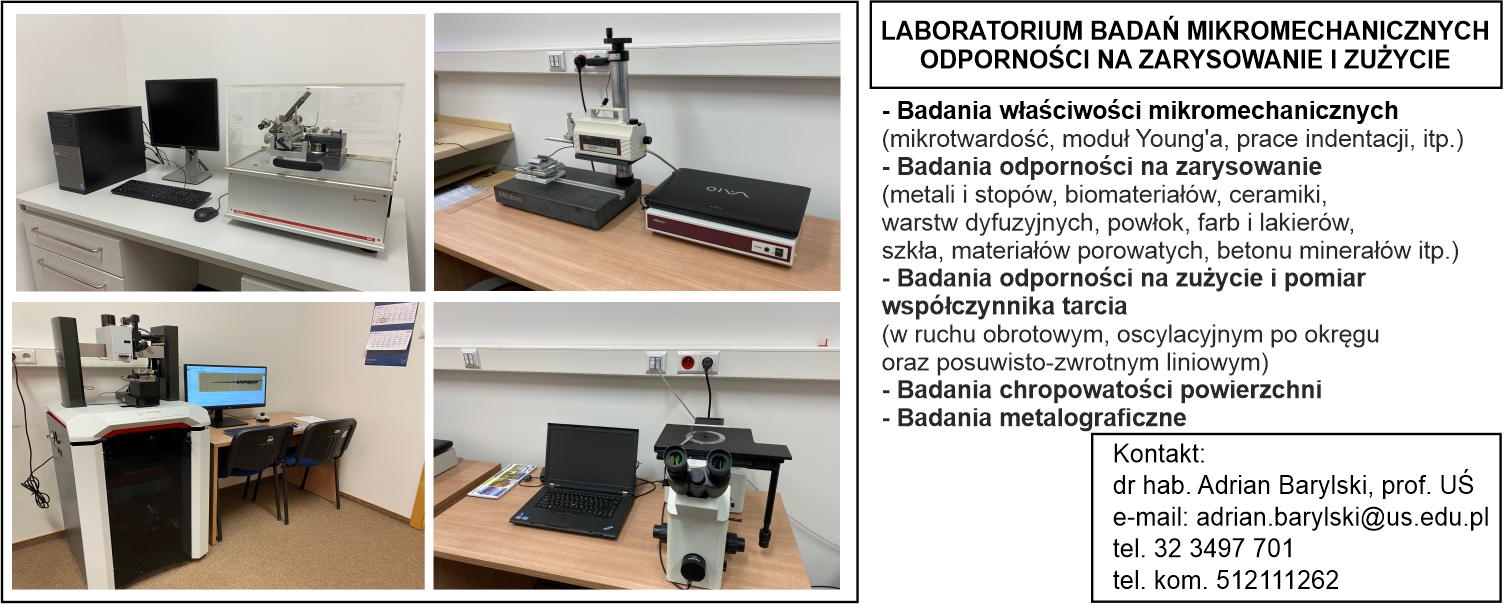

Laboratorium Badań Mikromechanicznych, Odporności na Zarysowanie i Zużycie

● inżynieria materiałowa ● inżynieria biomedyczna ● nauki fizyczne● nauki chemiczne ● nauki biologiczne ● nauki o ziemii i środowisku

● inżynieria materiałowa ● inżynieria biomedyczna ● nauki fizyczne● nauki chemiczne ● nauki biologiczne ● nauki o ziemii i środowisku